Quartzelec is a leading OEM-neutral independent global engineering group and a multi-disciplined service provider, delivering a comprehensive range of rotating machine electro / mechanical services and HV / LV contracting services.

Having an intimate working knowledge of the entire power chain in all sectors enables the company to engineer and deliver effective solutions, ensuring consistent machine availability and maintaining customers’ operating capacity and reputation.

Rotating machine services

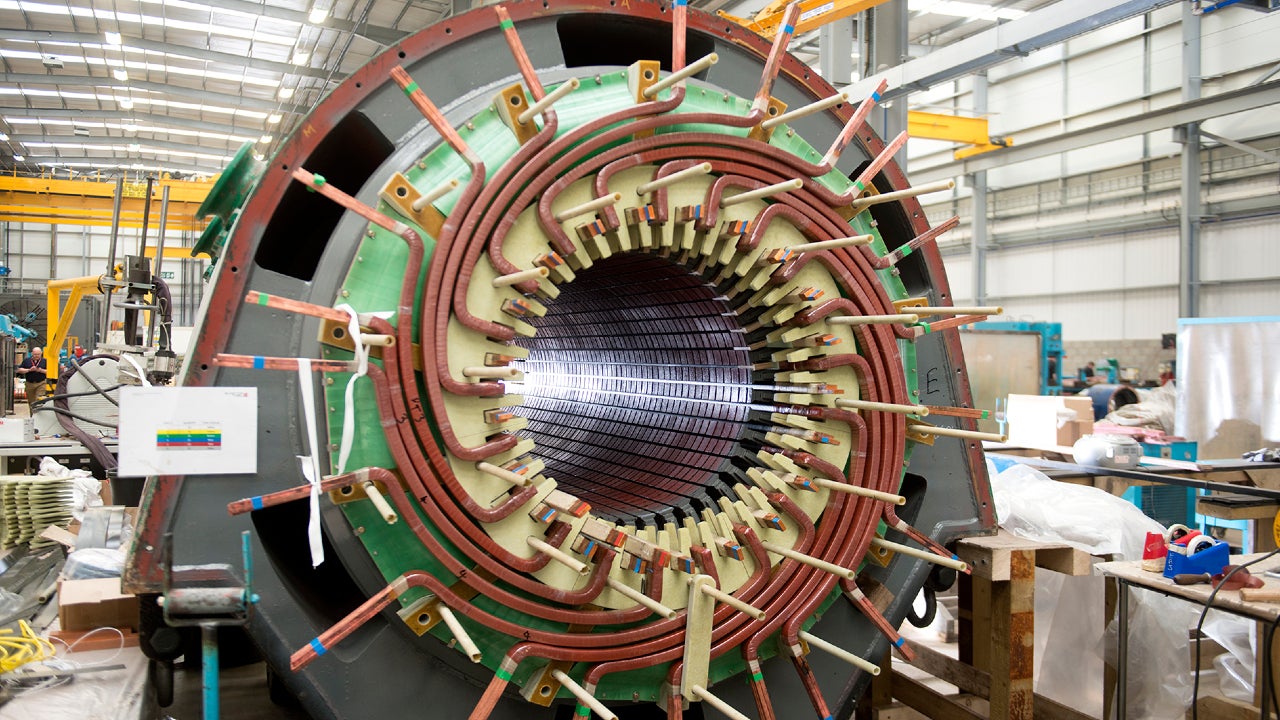

Quartzelec is a world-leading technical authority in the design and manufacture of AC / DC motors and generators with a comprehensive range of repair, maintenance, and service solutions, onsite or workshop. The company supports HV / LV machines to 600MW, AC motors and generators, DC machines, turbo-alternators, hydro-generators, submersible motors, and ancillaries.

Electrical contracting services

Quartzelec has the resources, scale, and accreditations to deliver projects efficiently, from grid connections, supply upgrades to HV / LV distribution with expertise in utility works, HV / LV construction, HV / LV maintenance, periodic test and inspection, and M&E services.

Innovative products for rotating machines

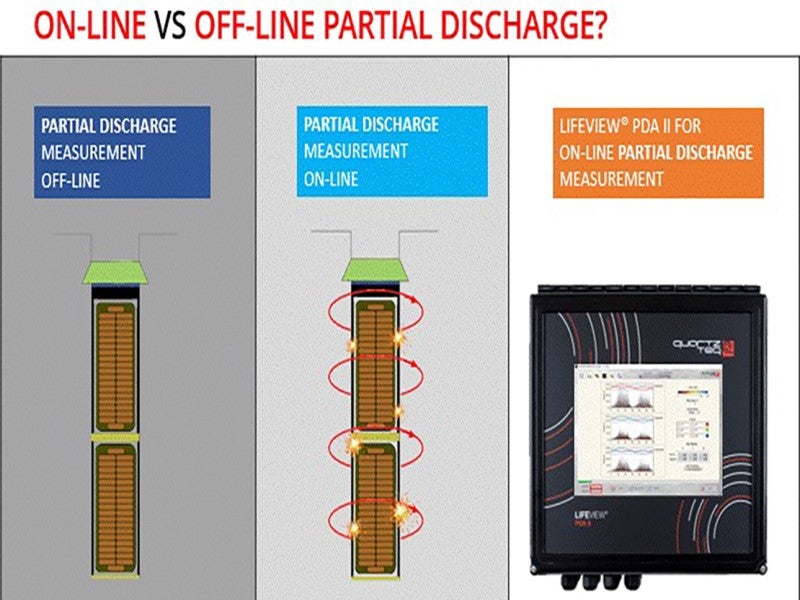

Our products are designed to protect and safeguard our clients’ assets throughout their lifespan. With solutions for new machines and retrofit, Quartzelec ensures safe and efficient operation in the harshest of environments through condition monitoring, fault-rated terminal boxes, protection and testing devices, replacement motors, OEM spares, AVR / excitation control systems, and machine coils and bars.

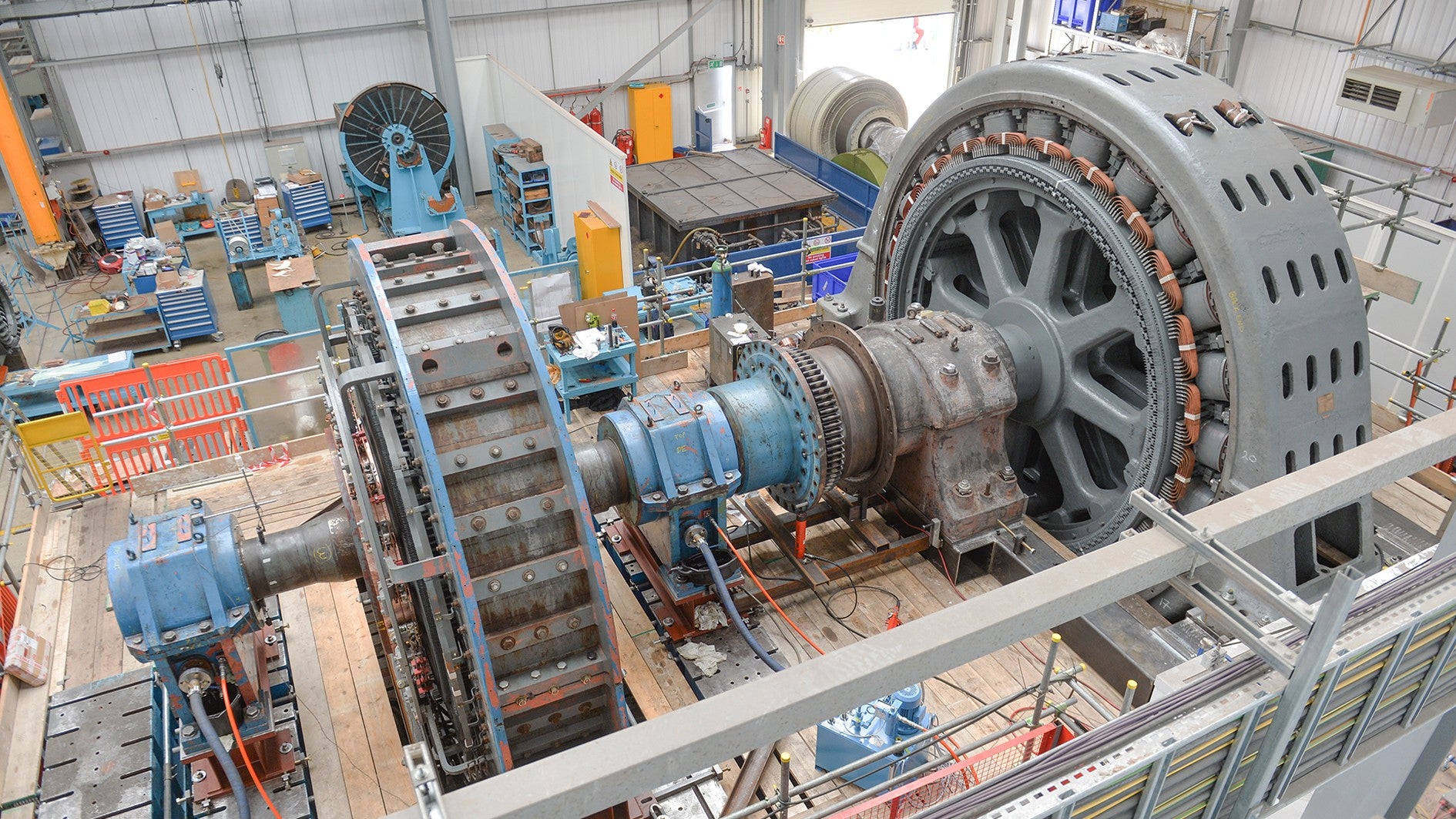

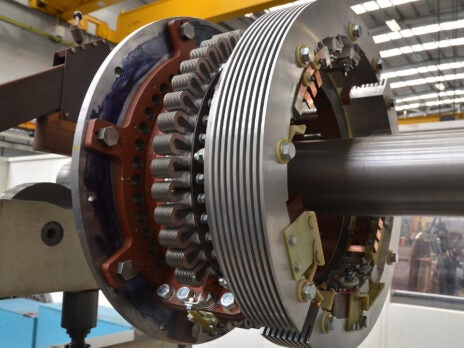

Machine service and overhaul

Quartzelec’s services for rotating electrical machines support steam / gas turbine generators, hydro generators, large AC motors, including FD, ID fan motors, BF and CW pump motors, and ancillaries, including excitation, protection, and control. The company supports any OEM machine / equipment, including legacy brands such as Unipak, I-Range, AK, Impak, and Flowpak, built by our heritage companies GEC, GEC Alsthom, ALSTOM, and Cegelec.

Major overhauls, windings, insulation, shafts, bearings, oil and hydrogen seals, couplings, retaining rings, and rotor and stator components can be replaced onsite or within a Quartzelec facility.

Rotating machine maintenance

Rotating machines will suffer electrical / mechanical stress, wear, overheat, corrode, and even catastrophically fail. Structured maintenance and repair are vital to avoid costly downtime and reduce the total cost of ownership.

Long-term service agreements (LTSAs) and life enhancement programmes (LEPs) ensure optimal reliability and efficiency, extending the life cycle of the asset wherever possible.

Our lifetime care and maintenance packages, from basic inspections to total risk management, include 24/7 support and breakdown response.

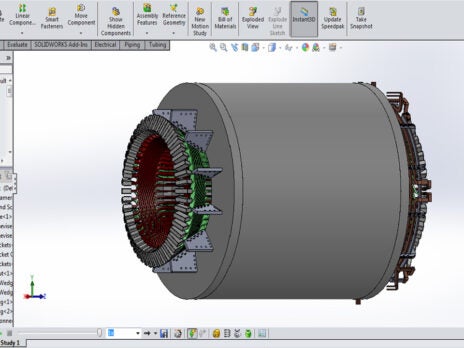

Design and engineering

OEM heritage is the core of our design engineering capabilities. Quartzelec is an engineering-focused business with a strong focus on reverse engineering to ensure interchangeable electrical / mechanical solutions.

In-house design / redesign of AC / DC machines, cores, windings, retaining rings, supports, blocking, and insulation ensures that manufacturing meets existing specifications.

We provide control and protection system designs, feasibility studies, and condition monitoring for IEP’s, excitation, and AVR system design, as well as solutions to existing design issues.

Testing and diagnostics

Extensive test facilities enable machines up to 100t to be tested in-house, with control room facilities enabling witness testing.

Onsite, Quartzelec engineers have comprehensive diagnostic tools for AC / DC machines for test and inspection from high voltage to insulation resistance. As troubleshooting experts, Quartzelec offers recalibration, in-situ balancing and laser realignment, and condition monitoring online / offline.

New equipment and spares

Spares for any OEM rotating machine can be supplied.

Our engineering excellence enables the design, manufacture, and reverse engineering of spares to OEM specifications. Equally, new equipment can be supplied, following a design review.

Only Quartzelec can design, manufacture, and supply capital spares and components for our legacy machines, including GEC, GEC Alsthom Large Machines, BTH, and AEI.

Rotating machine repair and refurbishment

Quartzelec provides repair, rewind, refurbishment, and retrofitting of all rotating machines up to 22kV, including static / rotating mechanical plant, workshop, and site-based.

The company also offers winding and re-insulation, cryogenic decontamination, and in-situ installation / replacement of components / ancillaries. On-site machining, including commutator skims for large DC drives, are among our capabilities. Turbo-alternator rotor repair is something Quartzelec excels at.

Installation and commissioning of rotating electrical machines

Installing and commissioning rotating machines and components of any OEM is a core service whether it is a repaired, refurbished, or new machine. Quartzelec can include protection systems, condition monitoring, ancillary control, instrumentation equipment, and excitation systems.

Site service for rotating machines

Our site services are diverse with a wide portfolio of support. Electrical maintenance, online or offline, non-destructive testing (electrical / mechanical), site safety, fire-detection system maintenance, condition-based maintenance, and value system maintenance through to operator and maintenance training are some of the services from Quartzelec provided at multiple sites around the world.

HV / LV contracting services

Quartzelec offers complete design, installation, commission, inspect, test, and maintenance from 415V to 33kV.

The company also supports construction projects, including new installations or refurbishments up to 33kV, providing switchgear, cabling, jointing, transformers, earthing, protection systems, and grading studies.

Our 24/7 emergency or routine maintenance support covers distribution systems to full building installations, switchgear maintenance to periodic inspection, and PAT testing. Flexible and tailored HV / LV maintenance packages are available for single / multiple sites, supporting manufacturers’ equipment.

The company serves M&E projects through the full design, installation, and commissioning, including LPHW, HVAC, BMS, plumbing, electrical, protective systems (fire & security), and data systems.

As a NERS-accredited ICP, Quartzelec designs networks, liaises with the DNO, provides new grid connections, and supplies upgrades up to and including 33kV.

Laser cutting and fabrication

TS Metals, a Quartzelec group company, is the company’s welding and fabrication business. Specialist metal fabricators and engineers deliver design, fabrication, manufacturing, and laser-cutting solutions for bespoke, complex, or turnkey projects from one-offs to batch production, supporting all industry sectors.

About Quartzelec

Our group philosophy enables us to deliver an integrated, engineering-led approach with best practice and shared vision as core values. Our engineering capability and design expertise deliver high-performance reverse-engineering solutions.

With more than 100 years of manufacturing experience, Quartzelec is derived from such electrical engineering giants as GEC, GEC Alsthom, BTH, AEI, and ALSTOM.

Motors and generators manufactured by the heritage companies are still supported by Quartzelec today. In fact, the company still holds the design and engineering records for many of these machines.