SIFCO Applied Surface Concepts (SIFCO ASC) is the global leader in selective electroplating and anodising service. They also offer a full line of plating equipment, manufacture quality chemical solutions and provide certified training worldwide.

SIFCO ASC has over 50 years’ experience in selective plating and its SIFCO Process® is regarded as the best in the industry. This includes comprehensive research and development and engineering support, a team of consultants and skilled technicians, as well as state-of-the-art plating equipment.

Selective plating for repairs and refurbishment in the Power Generation industry

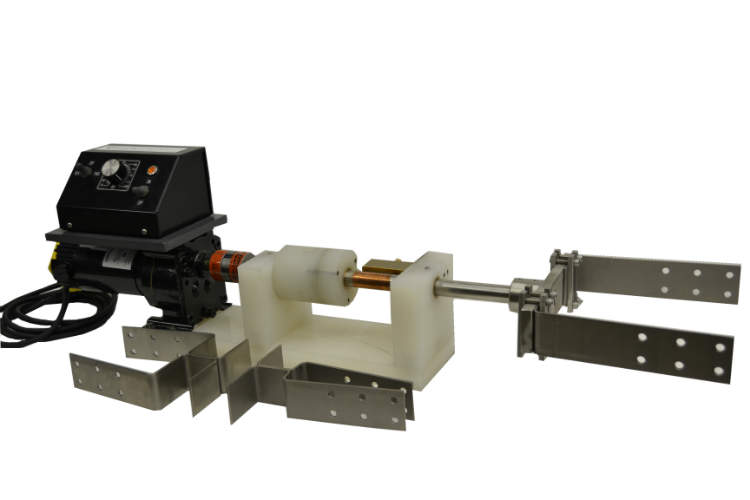

SIFCO ASC services the world’s leading players in the power generation industry using the SIFCO Process®. SIFCO ASC’s portable method of electroplating sections of a product without using immersion tanks is commonly used on original equipment manufacturer (OEM) products and for refurbishing mis-machined parts. With specially designed, portable equipment and plating technology, SIFCO ASC can repair damaged components on-site. This eliminates major delays associated with disassembly and shipping, minimising downtime.

There are numerous operational and maintenance challenges facing the power generation industry, such as component wear, corrosion, fretting and conductivity. SIFCO ASC surface treatments are used to decrease electrical contact resistance, improve wear resistance, improve corrosion resistance, and develop hard surfaces.

Electroplated deposits for engineering applications

The SIFCO Process® includes a full range of electroplated deposits that meet the demanding engineering requirements for bus bars, containment vessels, diesel engines, generators, nuclear components, turbine valves, turbines, bearing journals, slip rings, shafts and engine components.

Benefits of the SIFCO Process® include:

- Portable process for on-site repairs

- Minimal masking and disassembly

- Large parts can be processed

- Fewer delays in production and reduced downtime

- Quality controlled plating to specified thicknesses

- Reduced hydrogen embrittlement

- Environmentally friendly

- Efficient electrical power consumption

- Custom, engineered solutions

- Numerous industry approvals

- Quality plating results

- Superior technical knowledge and expertise

- Increased service life of components

On-site plating solutions

For customers that require service at their site, SIFCO ASC has a team of experienced technicians that can carry out selective plating at virtually any location.

SIFCO ASC’s skilled service technicians are experienced in plating a wide variety of materials and components and can recommend the best solution for our customers.

Industry approvals:

- AMS 2451

- MIL-STD 865 and 2197 (SH

- MIL-I-45208

- FAA Approved Repair Stations

- ISO 9001:2008

- AS9100C Registered Quality Management System

Discover the possibilities with the SIFCO Process®

Discover the SIFCO Process® and find out why selective plating is used for OEM applications as well as repairing and maintaining critical components for leading power generation, oil and gas, aerospace, precision engineering, electronic and many other leading organisations, worldwide.