Tallman Equipment Company is an established distributor of tools and equipment, serving a wide range of utility industries. Our expertise and skill are within the industrial, transmission and distribution, telecommunication and electric utility markets. Tallman offers our customers virtually any brand of tool from the leading manufacturers and suppliers in the industry.

We have exceptionally customer-focused sales and service team as we take the time to listen to you to get you the products or services you require. Tallman is staffed with expert tool specialists in each department that are readily available to advise you on the tooling or equipment that is ideal for your specific needs. At Tallman, we value our customers and believe that the customer is an extension of our company. Our team puts great effort in aligning our business practices with our faith to always do the right thing. Tallman is a name you can trust.

Tool and equipment rental solutions for the transmission and distribution industry

Tallman employs expert tool specialists, which offer advice on a wide range of tools and equipment to suit client needs.

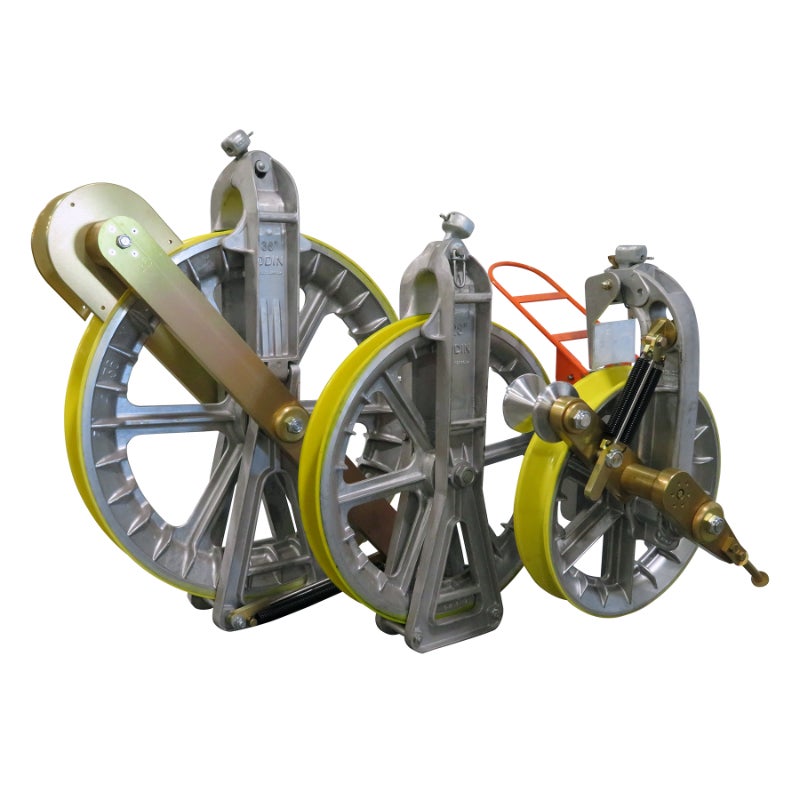

We supply a wide variety of common tools and equipment to rent to our customers. These tools are used for the construction and maintenance of electrical transmission systems.

Rental items include stringing blocks, travelling grounds, compression tools, dies, dynamometers, fiberglass extension arms, hoists and grips, hydraulic pumps and power units, platforms and hook ladders, as well as ground truck mats.

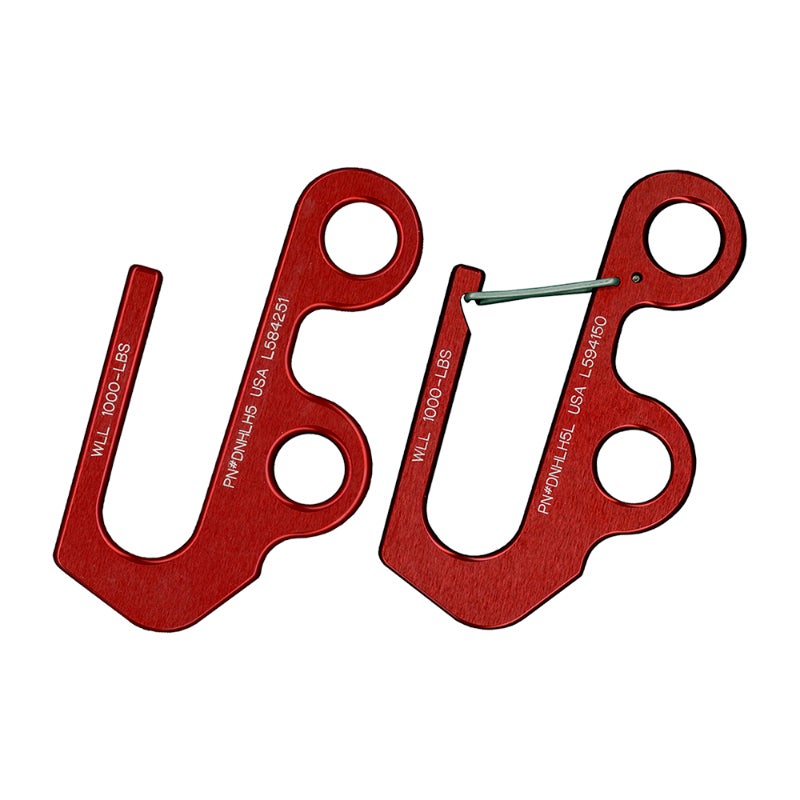

ASTM-certified custom ground and jumper sets

Tallman Equipment has a dedicated assembly department specialized in constructing, rebuilding and testing custom or standard-length ground and jumper sets.

Our products are designed to meet or exceed American Society for Testing and Materials (ASTM) standards.

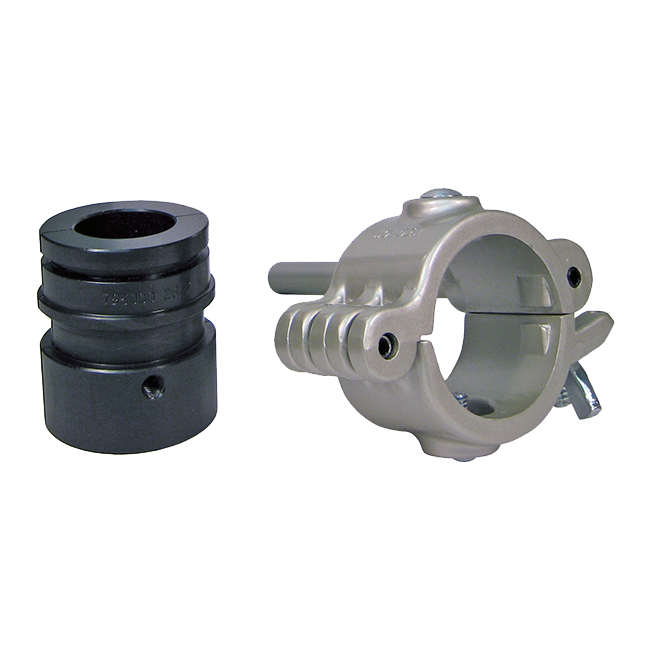

Fiberglass tool repair and refinishing for power applications

Tallman’s in-house fiberglass refurbishing technicians test and repair hot sticks, conductor gins, support gins, ladders, extension arms and shotgun sticks. Fiberglass tools and equipment are refurbished and fixed by staff in compliance with ASTM requirements.

Authorized warranty tool repair

We also provide an authorized warranty repair centre for several recognised brands of tools used in the industry. The facility offers accurate estimates for tool repair and quickly returns items upon completion.

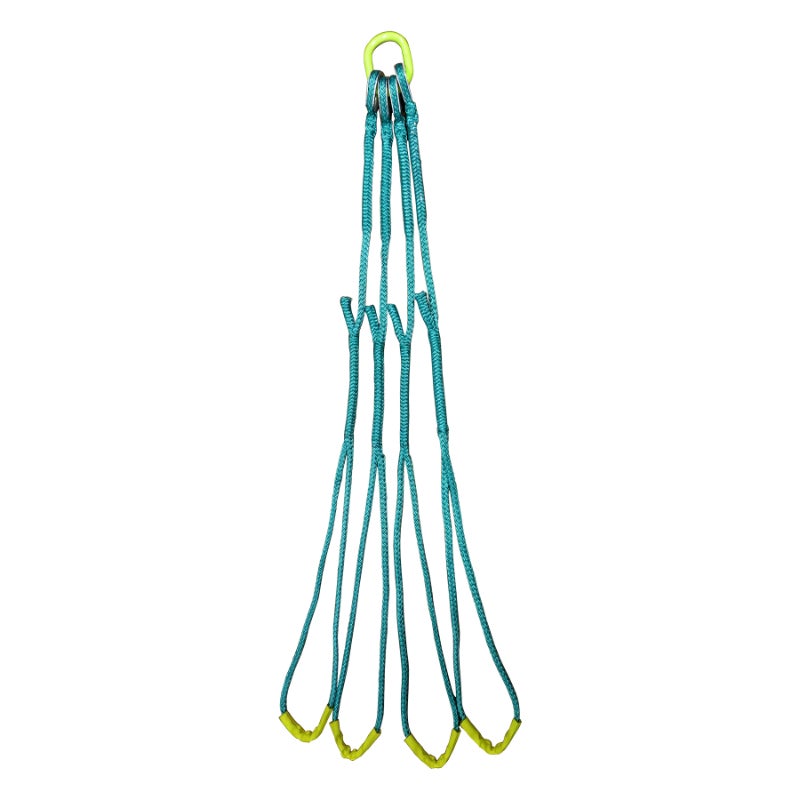

Custom rope manufacturing for energy sectors

Tallman Equipment is proud to have the services and experience of James Howell, who was the first to achieve certified Mastery for five splice variations through Samson’s Splicer Certification program.

James’s department assembles many custom rope products, including overhead, pad-mounted and capacitor bank transformer slings, as well as winch lines, high-strength tow ropes and custom rope assemblies.

All rope assemblies are tagged with part numbers, rope diameters, working load limits, safe handling instructions, serial numbers and test dates.